Reinforced Structural Design and Load DistributionEOM Industrial Dock Levelers are engineered with...

In the intricate world of logistics, Dock Levelers stand as vital components that not only streamline operations but also enhance safety, reduce costs, and improve hygiene conditions. These multifaceted devices have revolutionized the way goods are loaded and unloaded, transforming loading docks into efficient hubs of commerce.

Enhancing Logistics Efficiency

At the heart of Dock Levelers lies their ability to significantly boost logistics efficiency. By providing a mechanized and automated interface between the warehouse and the truck, they drastically improve the loading and unloading rates at the dock. This means shorter turnaround times for trucks, faster shipment processing, and ultimately, a more responsive supply chain. For exporters, the swift completion of container loading is paramount, as it minimizes waiting periods and maximizes the number of shipments handled within a given timeframe.

Cost Reduction and Resource Optimization

Dock Levelers contribute to cost savings in several ways. Firstly, by automating the loading and unloading process, they significantly reduce the need for manual labor, thereby lowering labor costs and minimizing the physical strain on workers. This allows businesses to reallocate their human resources towards more value-added tasks, enhancing overall operational efficiency. Furthermore, the reduction in manual handling also leads to fewer instances of damage to goods, further reducing costs associated with waste and replacements.

Safety First

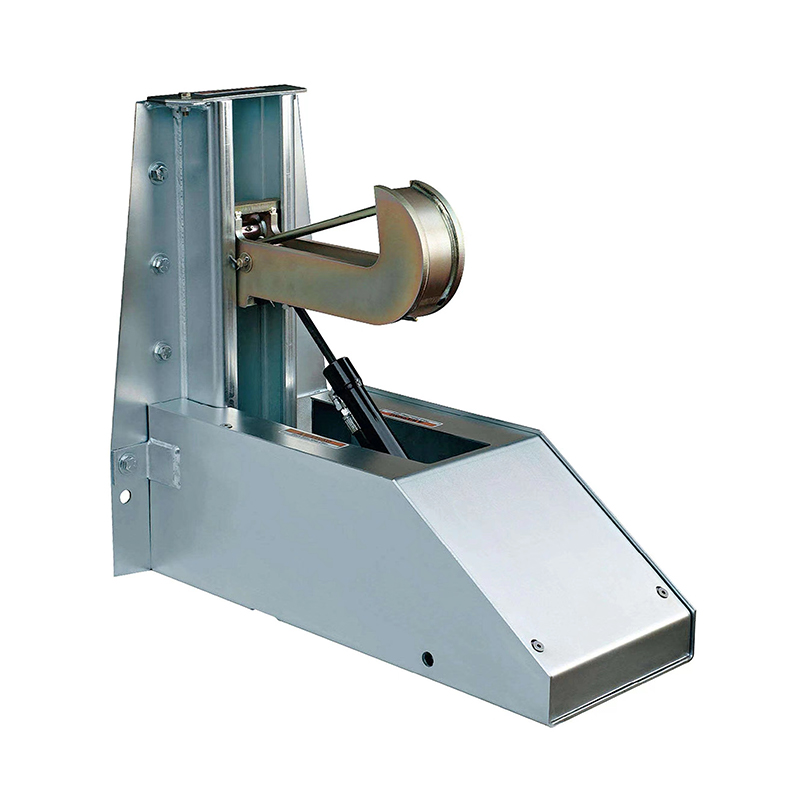

Safety is paramount in any logistics operation, and Dock Levelers play a crucial role in ensuring a safe working environment. Equipped with a range of safety features such as safety solenoid valves, rubber bumpers, and pinch-resistant skirting, these devices minimize the risk of accidents and protect both personnel and cargo. The elimination of manual lifting and heavy lifting equipment reduces the likelihood of workplace injuries, creating a safer and more secure workplace for all involved.

Improved Hygiene and Facility Longevity

Another often overlooked benefit of Dock Levelers is their contribution to improved hygiene and facility longevity. By facilitating the smooth and efficient movement of goods, they reduce the need for direct contact between personnel and cargo, thereby minimizing the spread of contaminants. Additionally, the reduced wear and tear on both the dock surface and truck beds due to more controlled and precise loading and unloading practices extend the lifespan of these critical infrastructure components.

Adaptable and Versatile Solutions

Modern Dock Levelers are designed with flexibility in mind, offering solutions tailored to specific operational needs. The integration of dock height adjustment plates, for instance, ensures seamless compatibility with a wide range of truck and trailer heights, eliminating the need for costly and time-consuming adjustments. This adaptability ensures that logistics operations remain efficient and unhindered, regardless of the variability in transportation vehicles.

Conclusion

Dock Levelers are indispensable tools in modern logistics, serving as catalysts for enhanced efficiency, cost savings, safety improvements, and better hygiene practices. By streamlining the loading and unloading process, they empower businesses to optimize their operations, protect their assets, and maintain a competitive edge in today's fast-paced market.

English

English Español

Español Tiếng Việt

Tiếng Việt