Self-Repairing Functionality for Continuous Operation A standout feature of the Anti-Crash Replay In...

Tight Seal Against Airborne Contaminants: Industrial-grade dock seals create a powerful, uninterrupted barrier between the external environment and the internal loading dock area, ensuring that airborne particles such as dust, dirt, exhaust fumes, and even fine particulates like pollen and industrial pollutants are kept at bay. In sectors like food processing, pharmaceutical manufacturing, and high-tech electronics assembly, this is not just a convenience—it's a regulatory necessity. Airborne contaminants can introduce foreign matter into products, compromise the sterile environment required in certain operations, or even lead to health code violations. Dock seals form a precise and consistent compression against the vehicle, effectively closing any gaps that could serve as entry points for unwanted particles, ensuring the air quality inside the dock area remains pure and uncontaminated.

Prevention of External Debris Infiltration: Loading dock areas are high-traffic zones, constantly exposed to external environmental conditions. Without proper sealing, debris such as leaves, gravel, waste, or windborne litter can easily invade these areas, creating an unsanitary and potentially hazardous workspace. Industrial-grade dock seals are designed to act as a physical barrier that prevents this debris from entering the loading zone during vehicle docking. Whether it's a light breeze carrying dust and leaves or heavier debris from nearby construction or parking lots, dock seals ensure that the interior space remains clean. This not only maintains operational hygiene but also reduces the frequency of cleaning operations, saving time, labor, and operational costs while ensuring that the environment complies with stringent cleanliness and safety standards.

Moisture Control and Prevention of Internal Contamination: Moisture is one of the most insidious sources of contamination in a loading dock environment, often leading to the growth of mold, mildew, and harmful bacteria. When a vehicle docks at a facility during inclement weather, rain, snow, or even condensation from temperature fluctuations can penetrate gaps around the dock door. Over time, this moisture can seep into the warehouse, creating damp areas where microorganisms can thrive. Industrial-grade dock seals create a watertight seal that prevents moisture from penetrating the loading area, significantly reducing the risk of water damage and microbial contamination. In industries where cleanliness and hygiene are paramount—such as food storage, pharmaceutical logistics, or chemical handling—this moisture control is not just about keeping the space dry; it’s about maintaining the integrity of the goods being processed or stored. Moisture ingress can also damage packaging and products, leading to costly losses.

Temperature Control for Hygiene Maintenance: Temperature control is a critical component in maintaining product integrity, particularly in industries dealing with perishable goods, temperature-sensitive materials, or frozen storage. Industrial-grade dock seals are essential for preserving temperature consistency by preventing the influx of outside air, which can lead to temperature fluctuations. Whether it's cold storage warehouses, freezers, or temperature-controlled production facilities, the presence of a tight dock seal ensures that conditioned air (whether hot or cold) remains inside the facility, while external air is kept out. This not only helps in maintaining optimal temperatures but also prevents condensation—another potential source of moisture-related contamination. The stable temperatures maintained by dock seals reduce the risk of spoilage, extend product shelf life, and prevent the growth of harmful bacteria, fungi, or other microorganisms that thrive in fluctuating environments.

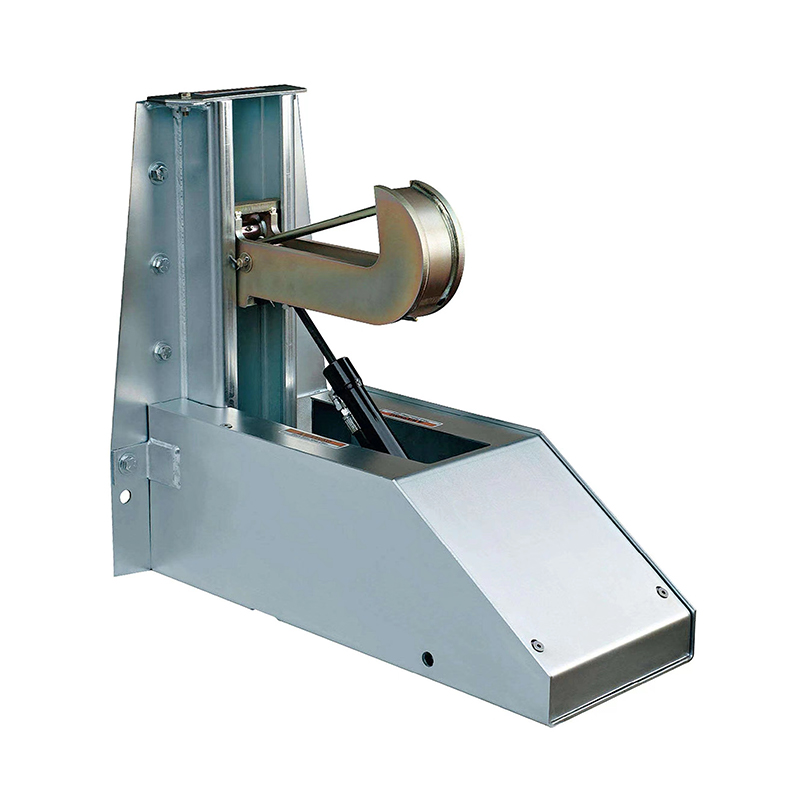

DS03 Industrial Inflatable Door Seal

English

English Español

Español Tiếng Việt

Tiếng Việt