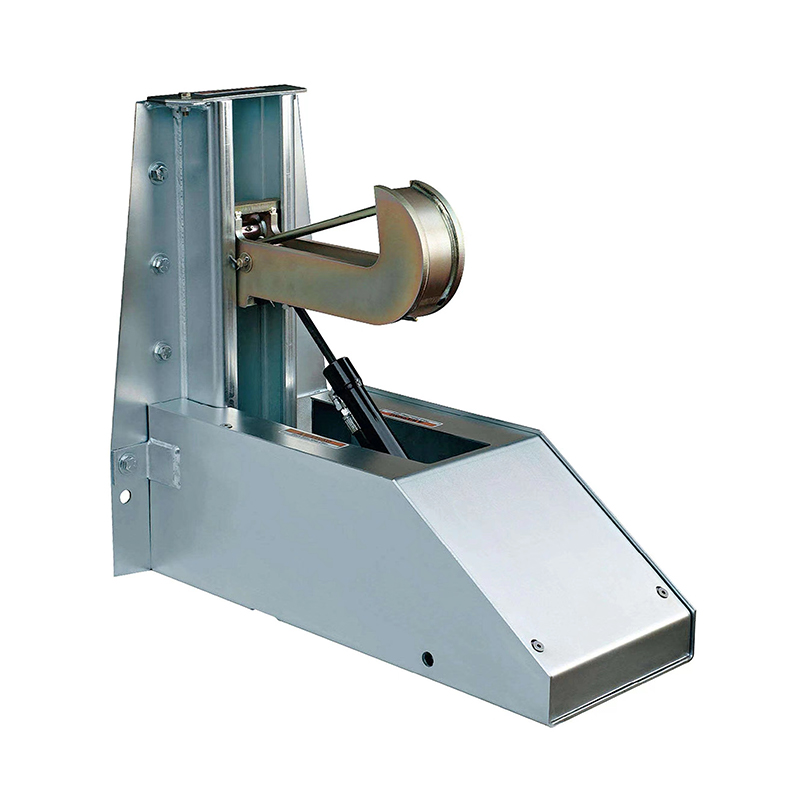

Adjustable Platform and Articulating Lip Design EOD Industrial Dock Levelers are engineered with a r...

The core benefit of rapid doors lies in their high-speed operation. In industrial settings where constant movement of goods, vehicles, and people is required, traditional doors with slow mechanisms can cause bottlenecks, leading to delayed processes. The rapid door’s quick open-close cycles (often within 3-5 seconds) are ideal for areas with high traffic volume, such as manufacturing floors, warehouses, and distribution centers. By reducing the time spent waiting for doors to open or close, businesses can ensure seamless transitions, preventing delays in product flow, and machinery operation, and employee movement. This, in turn, enhances throughput and reduces downtime, allowing for uninterrupted workflows.

Industrial environments, particularly those involved in temperature-sensitive operations such as cold storage, pharmaceutical manufacturing, or food processing, often require stable internal conditions to ensure product integrity and safety. Conventional doors that open slowly or remain open too long can result in excessive energy loss, increasing the operational cost of HVAC systems that need to compensate for heat or cold leakage. Rapid doors, with their quick cycle times, minimize the amount of time they are open, thus reducing the risk of energy waste. This contributes to cost savings by lowering energy consumption, particularly in facilities with stringent temperature controls.

The safety features integrated into industrial rapid doors are essential for reducing workplace accidents and minimizing downtime caused by equipment failures or worker injuries. Many rapid doors are equipped with advanced sensors that detect obstructions in the door’s path, immediately stopping or reversing the door’s movement. This feature helps prevent damaging collisions with vehicles, carts, or workers, which could otherwise lead to equipment malfunction or injuries. Furthermore, the design of these doors promotes a safe working environment by ensuring that personnel can move freely without worrying about being trapped or injured by heavy, slow-moving doors. By reducing the likelihood of accidents, the doors help ensure that operations run smoothly without interruptions, directly contributing to greater productivity and reducing operational downtime.

In fast-paced environments such as warehouses or distribution centers, efficient inventory management is crucial. The use of rapid doors aids in faster handling and movement of goods between different areas of the facility. These doors facilitate quick and unhindered loading and unloading of stock, enabling the timely processing of incoming shipments or outbound deliveries. The speed and reliability of the doors ensure that goods are transported without delay, leading to increased throughput and better inventory control. This is especially important in high-volume operations, where timely stock movement ensures that goods are always available when needed and that stock levels are maintained efficiently.

For industries that require strict hygiene standards, such as food processing, pharmaceuticals, and cleanrooms, maintaining a clean and controlled environment is paramount. Rapid doors help reduce the risk of contamination by minimizing the exposure time to external elements such as dust, moisture, and airborne particles. The quick opening and closing prevent extended exposure to contaminants from the outside, maintaining the integrity of sensitive areas. In addition, rapid doors can be designed with materials that resist dirt accumulation and are easy to clean, ensuring that high hygiene standards are consistently met without disrupting workflow.

English

English Español

Español Tiếng Việt

Tiếng Việt