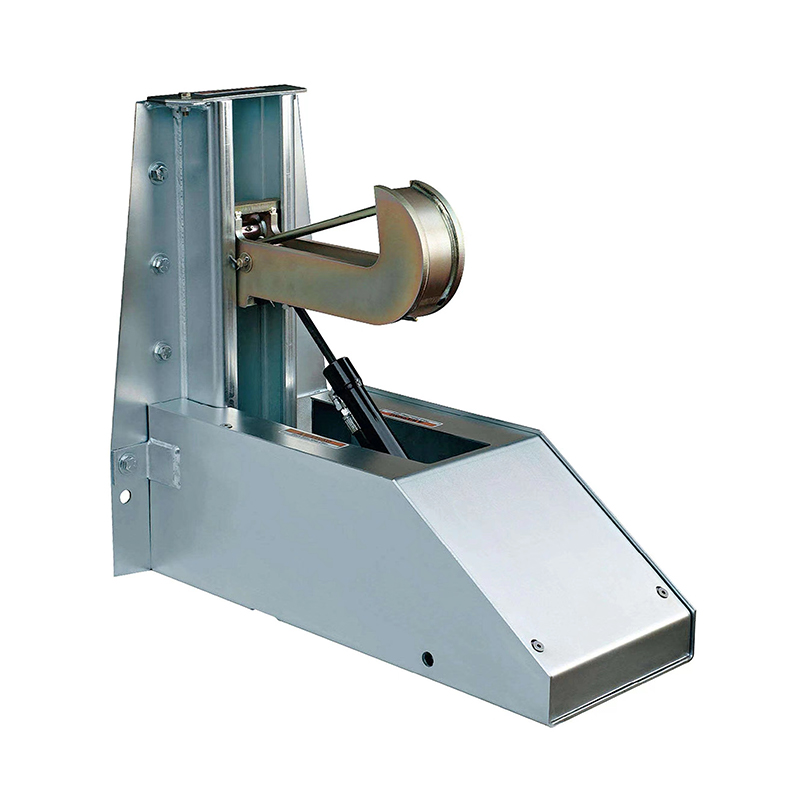

Reinforced Structural Design and Load DistributionEOM Industrial Dock Levelers are engineered with...

Before the installation of industrial fast speed doors, a comprehensive site assessment is essential. This evaluation considers various factors, including the layout of the space, expected traffic patterns (both pedestrian and vehicle), and the environmental conditions (such as temperature, humidity, and potential exposure to contaminants). This in-depth analysis ensures that the selected door type aligns with operational requirements, optimizing functionality and efficiency. In contrast, traditional door installations often follow standard specifications and dimensions, resulting in a more streamlined assessment process that may overlook specific site conditions.

The structural integrity of the installation site is critical for fast speed doors due to their weight and operational dynamics. These doors may require reinforced framing and specific mounting hardware to handle the stresses associated with rapid opening and closing. This could include additional bracing or support beams to ensure stability during operation. Traditional doors typically rely on standard wooden or metal frames and hinges that do not necessitate such enhancements, leading to a simpler installation framework.

Industrial fast speed doors integrate complex electrical components that facilitate their high-speed operation. This includes installing motors, control panels, and various safety sensors that require careful wiring and configuration. The installation must ensure that all electrical connections comply with industry safety standards, often necessitating the involvement of qualified electricians or technicians. Traditional doors, by contrast, may operate purely through manual mechanisms or basic mechanical systems, which eliminates the need for extensive electrical integration and reduces installation complexity.

The mounting mechanisms for fast speed doors are designed to support their unique operational requirements. These mechanisms typically involve tracks and guides that allow the door to move vertically or horizontally with minimal resistance. The alignment of these components is crucial, as even minor misalignments can affect the door’s performance and safety. Conversely, traditional doors typically rely on straightforward hinge or sliding mechanisms that do not require intricate mounting arrangements, making their installation process relatively simple.

Safety features are a paramount consideration in the installation of fast speed doors. These doors often include advanced safety systems such as motion detectors, light curtains, and emergency stop mechanisms that must be integrated seamlessly into the overall design. The placement of these components requires careful planning to ensure that they operate effectively without obstructing door movement. Traditional doors may have simpler safety features, which reduces the complexity of their installation and the need for extensive configuration.

Following installation, industrial fast speed doors undergo a thorough programming and testing phase to ensure they operate correctly and safely. This process includes configuring control systems, setting speed parameters, and calibrating safety sensors to respond accurately to the environment. Comprehensive testing is critical to validate that all components work in unison, ensuring reliable operation under various conditions. Traditional doors do not typically require such extensive programming or testing, as their operation is more straightforward and primarily manual.

Fast speed doors require specific spatial considerations due to their operational dynamics. Adequate overhead and lateral space must be provided to accommodate the door’s full range of motion, which includes both opening and closing sequences. This requirement helps prevent collisions with nearby structures or equipment during operation. In contrast, traditional doors may necessitate clearance primarily for swinging or sliding but generally require less overall space due to their less dynamic movement.

English

English Español

Español Tiếng Việt

Tiếng Việt