Adjustable Platform and Articulating Lip Design EOD Industrial Dock Levelers are engineered with a r...

1. Loading and unloading efficiency and adaptability:

When selecting a hydraulic loading and unloading platform, the first considerations are its loading and unloading efficiency and its ability to meet the needs of the specific working environment. The DL-1000 hydraulic loading and unloading platform is known for its excellent horizontal loading and unloading capabilities. It can quickly and smoothly dock trucks of different heights, greatly shortening loading and unloading time and improving logistics efficiency. In addition, the design of DL-1000 fully considers the diversity of cargo types. Whether it is heavy cargo or lightweight items, efficient loading and unloading can be achieved by adjusting platform parameters. This flexibility makes DL-1000 widely used in various logistics centers, warehouses, factories and other places, becoming a key device to improve overall operational efficiency.

2.Safety performance:

Safety is an indispensable core element of hydraulic loading and unloading platforms. The DL-1000 performs well in terms of safety. The safety maintenance support pole it is equipped with provides workers with solid support during maintenance or cleaning, effectively avoiding the risk of accidental falls. At the same time, the design of the safety valve and safety block adds a layer of protection to the operation process, ensuring that in the event of unexpected truck movement and other emergencies, the loading and unloading platform can respond quickly to prevent accidents. In addition, the durability of the swing lip further improves the safety of the platform and avoids stress cracking problems caused by long-term use.

3.Material and durability:

The DL-1000 hydraulic loading and unloading platform also puts great effort into the material selection. The swing lip uses a 16mm thick veneer. This material not only has excellent load-bearing capacity, but also maintains stable performance during long-term use and is not prone to stress cracking and other problems. The mainboard profile is carefully composed of multiple C-shaped steel profiles. This structural design not only enhances the strength and torsion resistance of the mainboard, but also makes the platform more stable and reliable when bearing heavy loads. Overall, the material selection and structural design of DL-1000 fully consider the durability requirements, ensuring that the platform can withstand harsh working conditions.

4. Long-term use effect under environmental conditions.

Stability and reliability of hydraulic system:

The hydraulic system is the core power source of the hydraulic loading and unloading platform. DL-1000 uses 99.9% imported hydraulic units. This choice not only ensures the sealing and working stability of the hydraulic system, but also ensures its reliable performance under long-term, high-intensity work. The imported hydraulic unit has reached high standards in terms of material, workmanship and performance, which can effectively reduce the failure rate and extend the service life. In addition, the hydraulic system of DL-1000 has been carefully designed and debugged to ensure the stability and accuracy of the platform during the lifting process, further improving loading and unloading efficiency and safety.

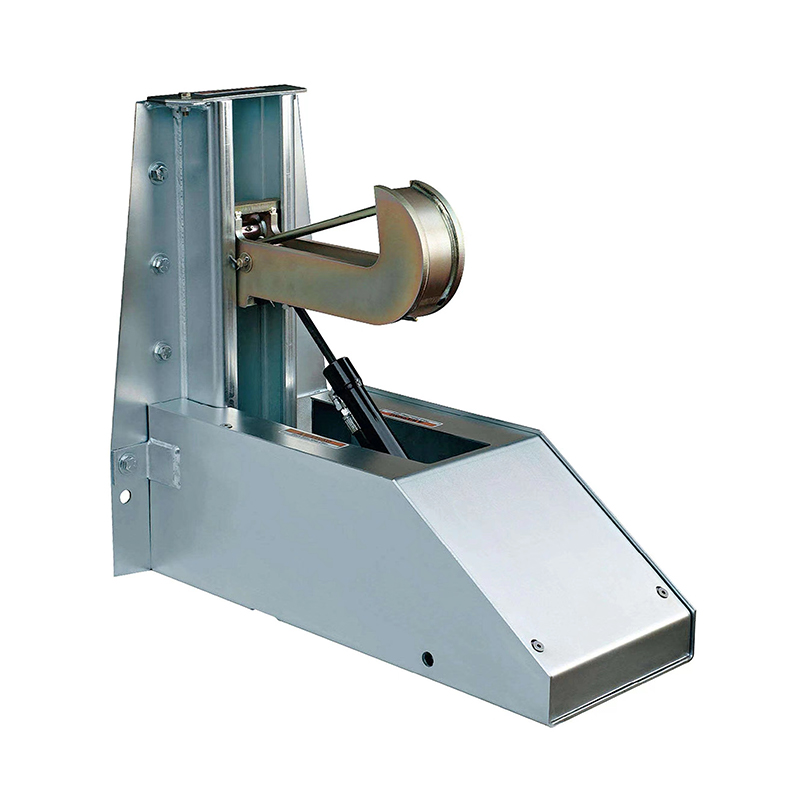

5. Optional accessories and customized services:

The DL-1000 hydraulic loading and unloading platform provides a wealth of optional accessories and customized services to meet the individual needs of different users. Users can choose appropriate accessories based on the actual working environment and cargo characteristics, such as dual hydraulic lifting systems, open hinges, non-standard loads and sizes, etc. The addition of these accessories can not only improve the performance and applicability of the platform, but also further meet the specific needs of users. In addition, DL-1000 also supports surface treatment processes such as galvanizing to improve the corrosion resistance and aesthetics of the platform. By providing customized services, the DL-1000 hydraulic loading and unloading platform can create a working environment that is more in line with actual needs for users and improve overall operational efficiency.

6. After-sales service and technical support:

When choosing a hydraulic loading and unloading platform, after-sales service and technical support are equally important. The supplier of DL-1000 hydraulic loading and unloading platform knows this well and therefore provides users with comprehensive after-sales service and professional technical support. Whether it is equipment installation and commissioning, routine maintenance or troubleshooting, suppliers can respond quickly and provide professional solutions. In addition, the supplier also provides users with comprehensive training services to help users better master the use and maintenance skills of the equipment. This comprehensive after-sales service and technical support not only enhances user satisfaction and trust, but also ensures the stability and reliability of the equipment during long-term use.

English

English Español

Español Tiếng Việt

Tiếng Việt