Adjustable Platform and Articulating Lip Design EOD Industrial Dock Levelers are engineered with a r...

In busy logistics centers and warehouses, fast and safe loading and unloading of goods is the key to ensuring operational efficiency. As an important part of this process, Hydraulic Dock Levelers have undoubtedly become an indispensable part of the modern logistics system with its precise docking, efficient and stable working characteristics. The following will specifically introduce the working principle of Hydraulic Dock Levelers and reveal the technical secrets behind it.

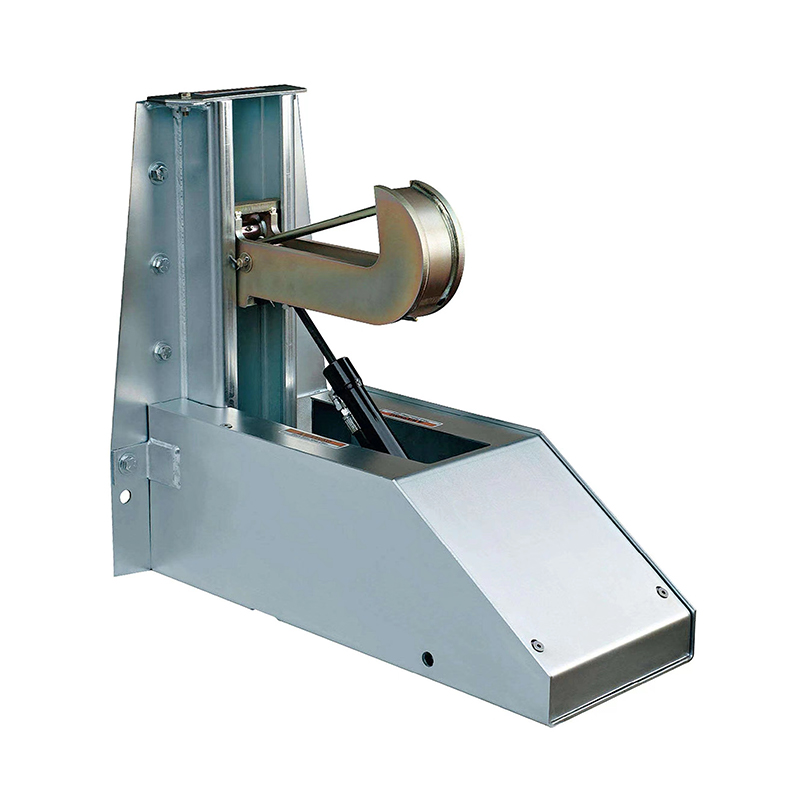

Hydraulic Dock Levelers realize their lifting function through a hydraulic system. Its core components mainly include hydraulic pumps, cylinders, control valves and corresponding transmission mechanisms. When a truck or container truck enters the loading and unloading area and docks at a preset position, the hydraulic loading and unloading platform begins to play its role.

When starting work, start the hydraulic pump first. As the power source of the entire system, the hydraulic pump is responsible for pumping hydraulic oil from the tank and pressurizing it into the cylinder. As the oil pressure increases, the piston in the cylinder begins to be pressurized and moves upward along the cylinder body. This process is achieved through the precise adjustment of the control valve to ensure the lifting speed and stability of the cylinder. The rise of the oil cylinder drives the rise of the loading and unloading platform board connected to it. The platform board is usually made of high-strength, wear-resistant materials to ensure that it can withstand the weight of the goods and frequent loading and unloading operations. As the platform board gradually rises, the gap between it and the bottom plate of the truck or container gradually decreases until seamless docking is achieved. During the docking process, the hydraulic loading and unloading platform is also equipped with a series of safety protection devices to ensure the safety and reliability of the operation. The limit switch can monitor the rising height of the platform board. Once it reaches the preset position, it will automatically cut off the power supply of the hydraulic pump to prevent the platform from rising too much. At the same time, the design of safety edges and buffer pads can also effectively prevent the goods from colliding or slipping during loading and unloading. When the loading and unloading operation is completed, the hydraulic loading and unloading platform needs to be restored to the initial position for the next use. The control valve will adjust the flow direction of the hydraulic oil so that the piston in the oil cylinder gradually descends under the action of gravity and spring force, driving the platform board back to the ground. The whole process is also smooth, rapid, safe and controllable.

Hydraulic Dock Levelers achieve precise docking between loading and unloading platforms and trucks or containers through precise control and efficient operation of the hydraulic system. This technology improves loading and unloading efficiency, reduces labor intensity, and ensures the safety and reliability of goods and loading and unloading equipment. In the modern logistics system, the hydraulic loading and unloading platform is undoubtedly an indispensable behind-the-scenes hero.

English

English Español

Español Tiếng Việt

Tiếng Việt