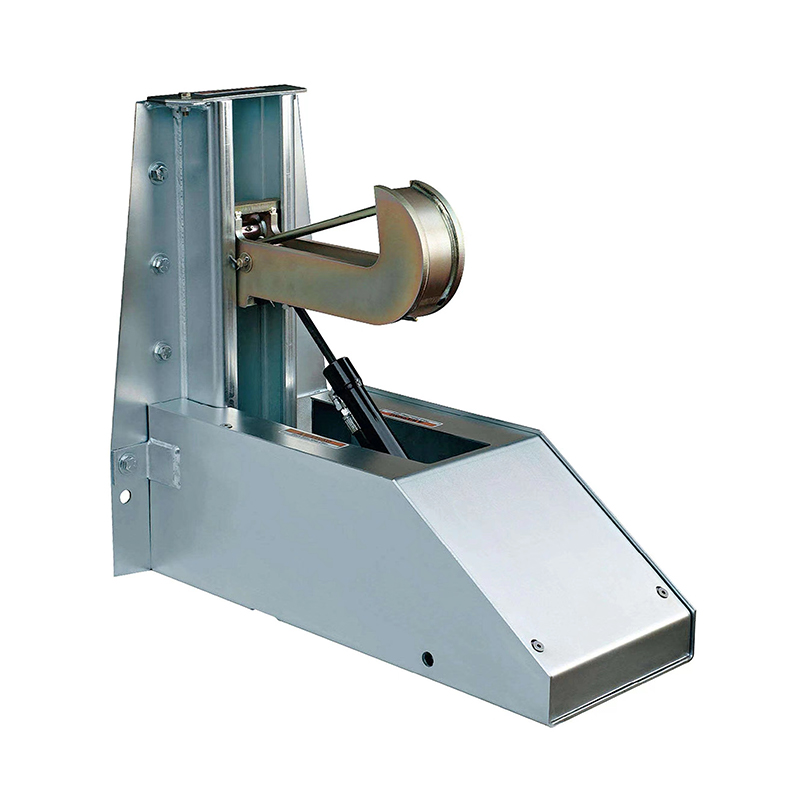

Adjustable Platform and Articulating Lip Design EOD Industrial Dock Levelers are engineered with a r...

One of the primary functions of industrial-grade dock seals is to minimize the exchange of air between the warehouse interior and the outside environment. Dock seals are engineered to create a tight, airtight seal around the dock door when the delivery truck is backed up to the dock. This airtight barrier prevents warm air from infiltrating the warehouse during cold weather, and conversely, it blocks cold air from entering the warehouse during warm conditions. By controlling air movement, dock seals help to maintain the temperature integrity of the warehouse, keeping climate-sensitive products in optimal conditions and reducing the need for excessive heating or cooling from the HVAC systems.

In warehouses where temperature regulation is critical, such as cold storage facilities or climate-controlled environments, the role of dock seals in preventing energy loss is significant. By effectively sealing the gaps around the dock, industrial-grade dock seals prevent conditioned air (whether heated or cooled) from escaping. This ensures that the warehouse’s internal temperature remains consistent during the loading and unloading process. In facilities handling temperature-sensitive goods like pharmaceuticals, perishable food, or chemicals, the energy efficiency provided by these seals can significantly reduce operating costs by minimizing the need for constant climate control and preventing energy waste.

Moisture infiltration can cause a range of problems, from product degradation to increased humidity levels that can affect both warehouse conditions and product quality. Dock seals are designed to prevent moisture and dust from entering the warehouse during loading and unloading. They achieve this by creating a secure barrier that helps prevent rain, snow, or humidity from infiltrating the warehouse space, especially during stormy weather conditions. This barrier is especially crucial in environments that require low humidity levels or where moisture-sensitive products are stored, as it prevents product contamination and helps maintain the required temperature and humidity levels.

The design and material composition of industrial-grade dock seals are often optimized for insulation. Many high-quality dock seals are constructed using insulated fabrics or foam-filled materials, which add an extra layer of thermal protection around the dock door area. This insulation helps to regulate the internal temperature of the warehouse, improving the overall thermal efficiency of the space. By acting as a thermal barrier, the seal limits the effect of external temperature fluctuations, ensuring that the warehouse remains at a stable, controlled temperature.

In many warehouses, the configuration of loading docks may vary, with different truck sizes or dock door shapes. Industrial-grade dock seals are designed to be flexible and adaptable to different truck configurations, ensuring that the seal remains effective regardless of truck size or the loading dock's design. This adaptability ensures a consistent temperature differential between the warehouse interior and the external environment, even when various types of trucks are used. The flexibility of the seal ensures that it can conform to the unique shape of each delivery vehicle, thereby preventing temperature fluctuations during the loading and unloading process and maintaining the required internal conditions.

For industries such as food distribution, pharmaceuticals, and logistics that rely on cold chain management, the continuous and consistent maintenance of specific temperatures is critical to ensuring product safety and quality. Industrial-grade dock seals play a pivotal role in ensuring that external conditions do not disrupt the cold chain during loading and unloading. By preventing external warm air from infiltrating refrigerated trucks and ensuring that cold air doesn’t escape from the warehouse, dock seals help maintain the precise temperature range needed to preserve goods.

English

English Español

Español Tiếng Việt

Tiếng Việt