Reinforced Structural Design and Load DistributionEOM Industrial Dock Levelers are engineered with...

Efficient Loading and Unloading: Vertical standing dock levelers create a smooth bridge between the dock floor and the trailer bed, ensuring efficient and safe transfer of goods. This capability is essential for handling diverse cargo types, including heavy pallets, forklifts, and bulk shipments. By minimizing height differences and gaps, they reduce the risk of accidents and product damage, thereby improving overall operational productivity.

Temperature-Controlled Environments: Facilities that rely on strict temperature control, such as cold storage warehouses and refrigerated logistics centers, benefit greatly from vertical dock levelers. The vertical design allows dock doors to close tightly against the floor when the leveler is not in use, significantly reducing air exchange and maintaining interior temperature stability. This minimizes energy consumption and helps comply with food safety standards and regulations.

Hygienic Applications: Industries that prioritize cleanliness and hygiene, such as food processing, pharmaceuticals, and healthcare, often face challenges in controlling contamination. Vertical standing dock levelers enhance hygiene by sealing the dock area when not in use, preventing the entry of dust, pests, and other contaminants. This is particularly critical for facilities that must comply with stringent industry regulations, such as FDA or HACCP standards.

Space Optimization: Space is often at a premium in industrial facilities, particularly in urban areas or high-traffic docks. The vertical storage position of these dock levelers ensures that they take up minimal floor or dock space when not in use. This space-saving design allows facilities to allocate more area for operations, storage, or maneuvering equipment, maximizing overall efficiency.

Secure Dock Operations: Security is a priority for facilities dealing with valuable or sensitive goods. Vertical dock levelers enhance dock security by keeping the doors closed when the leveler is idle. This reduces the risk of unauthorized access, theft, and vandalism, providing an additional layer of protection for goods and personnel.

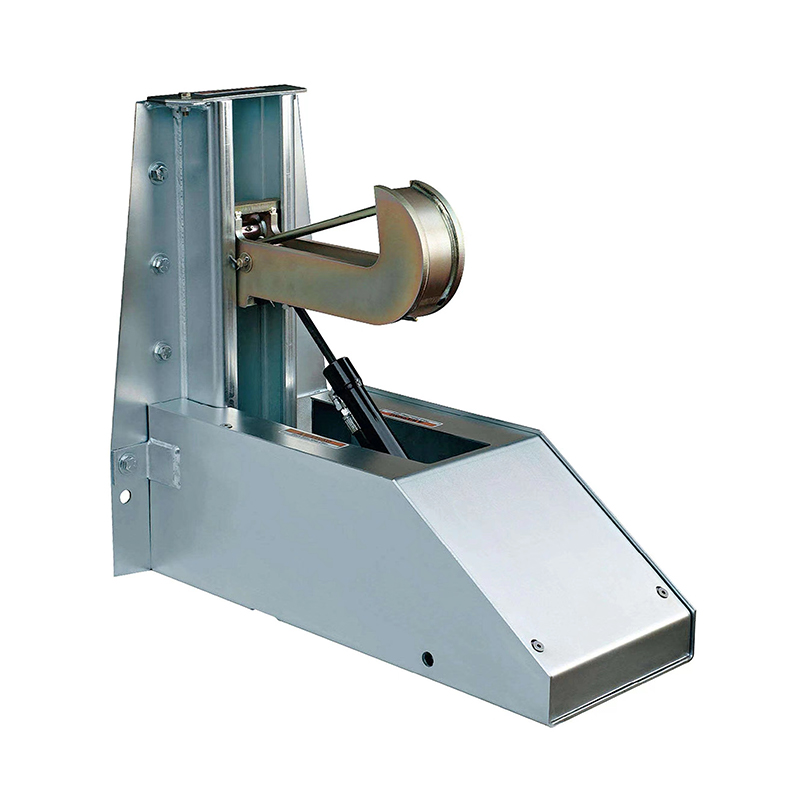

Adaptability to Varying Trailer Heights: One of the standout features of vertical standing dock levelers is their ability to accommodate a wide range of trailer heights. This versatility ensures compatibility with different truck models and loading requirements, reducing downtime and enhancing operational flexibility. Whether handling low-bed trailers or high-clearance vehicles, these levelers provide a stable and adjustable platform.

Heavy-Duty Applications: Designed to handle substantial weight capacities, vertical standing dock levelers are ideal for facilities managing heavy machinery, industrial equipment, or large quantities of goods. Their robust construction ensures they can withstand the demands of high-load operations, providing reliability in environments where durability is paramount.

Logistics and Distribution Centers: In high-volume logistics and distribution centers, efficiency is critical to meeting tight schedules and turnaround times. Vertical dock levelers facilitate quick and seamless access to trailers, minimizing loading and unloading times. Their ability to support continuous operations makes them indispensable for industries like retail distribution, manufacturing supply chains, and third-party logistics providers.

English

English Español

Español Tiếng Việt

Tiếng Việt