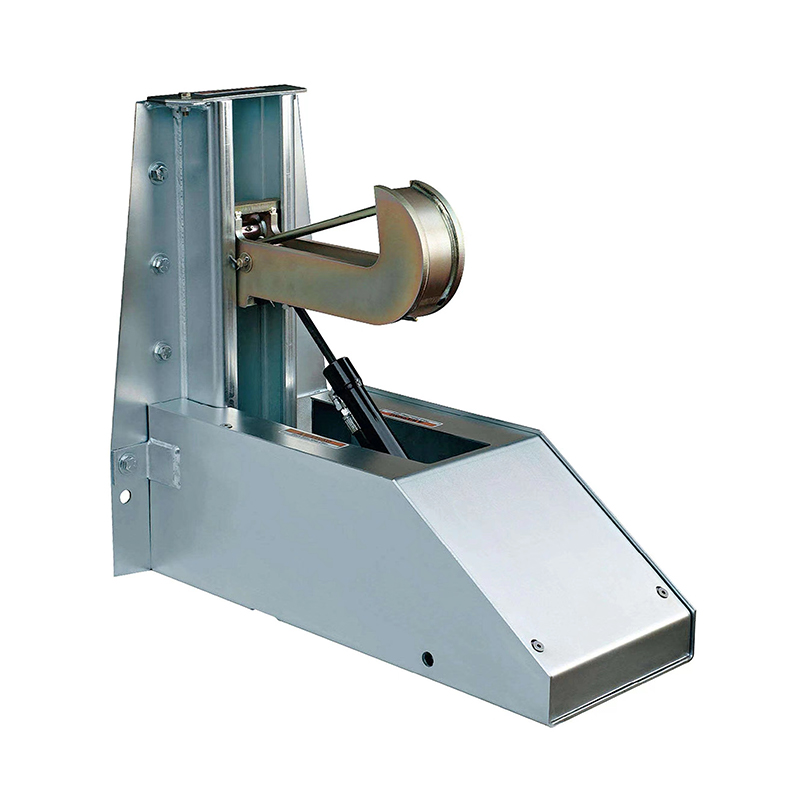

The locking mechanism is one of the most crucial components of a industrial vehicle horizontal hook ...

Air Mixing and Destratification: One of the primary functions of industrial ceiling fans is destratification, the process of mixing warm air trapped at the ceiling with cooler air at ground level. In large, open spaces with high ceilings, temperature differences often form, with warmer air collecting near the ceiling and cooler air staying closer to the floor. Industrial ceiling fans counteract this effect by constantly circulating the air, allowing the warm air to move downwards and mix with the cooler air. This reduces thermal stratification and creates a more consistent temperature profile across the entire space. The result is a more comfortable environment, as temperature differences between the ceiling and floor are minimized, which is particularly important in environments where temperature consistency is critical for operations, safety, and comfort.

Horizontal and Vertical Air Movement: Industrial ceiling fans are designed to produce a large volume of air at low speeds, which results in both horizontal and vertical air movement. The fan blades are engineered to circulate air not only from the top to the bottom of the space but also to spread the airflow across the width of the room. This comprehensive air distribution ensures that even the farthest corners of a room are reached. In large spaces like factories and gyms, which often have irregularly shaped layouts or areas with limited airflow, this horizontal spread of air helps eliminate hot or cold spots, ensuring that the temperature remains consistent throughout. The effective mixing of air across the entire room makes it easier to maintain a uniform temperature, preventing localized imbalances that could affect both human comfort and operational efficiency.

Energy Optimization with HVAC Systems: When integrated with existing heating, ventilation, and air conditioning (HVAC) systems, industrial ceiling fans can significantly improve energy efficiency. By promoting air circulation and destratification, these fans allow HVAC units to operate more effectively by reducing the temperature gradient between the ceiling and the floor. For instance, in winter months, when heating systems are working to maintain a warm environment, the fan helps distribute the heat more evenly, reducing the need to overheat certain areas. In summer, the fan can be used to support air conditioning units by keeping the air moving, which can allow the air conditioning system to operate at a more moderate level. This reduces overall energy consumption and can lower operational costs over time by ensuring HVAC systems don’t have to work as hard to maintain desired temperatures.

Comfort Enhancement for Occupants: Industrial ceiling fans enhance comfort by improving airflow across the space, which increases the evaporation rate of sweat from the body, leading to a cooler perceived temperature even without drastically lowering the actual room temperature. This can be especially beneficial in spaces where workers or visitors may be engaged in physical activities or manual labor. By improving comfort without requiring drastic changes to the HVAC settings, these fans can help maintain a more sustainable and pleasant working or recreational environment, thereby reducing the risk of heat stress and discomfort.

Reduced Hot and Cold Spots: Large, open spaces are prone to uneven temperature distribution due to the size and shape of the area, as well as the variable nature of air circulation. Without proper airflow, certain areas—especially those far from windows, doors, or HVAC vents—can experience temperature imbalances. Industrial ceiling fans reduce these hot and cold spots by ensuring that air circulates evenly across all areas of the room. The even distribution of air not only promotes comfort but also helps protect sensitive machinery, electronics, and materials that may be vulnerable to temperature extremes.

English

English Español

Español Tiếng Việt

Tiếng Việt