Reinforced Structural Design and Load DistributionEOM Industrial Dock Levelers are engineered with...

In the fast-paced world of logistics and supply chain management, Dock Levelers play a pivotal role in ensuring smooth and efficient operations between warehouses and delivery trucks. Yet, despite their crucial function, many outside the industry may not be fully aware of what these essential tools are, how they work, or the significance they hold in maintaining the flow of goods. This article aims to shed light on the intricacies of Dock Levelers and their indispensable role in modern distribution systems.

What Are Dock Levelers?

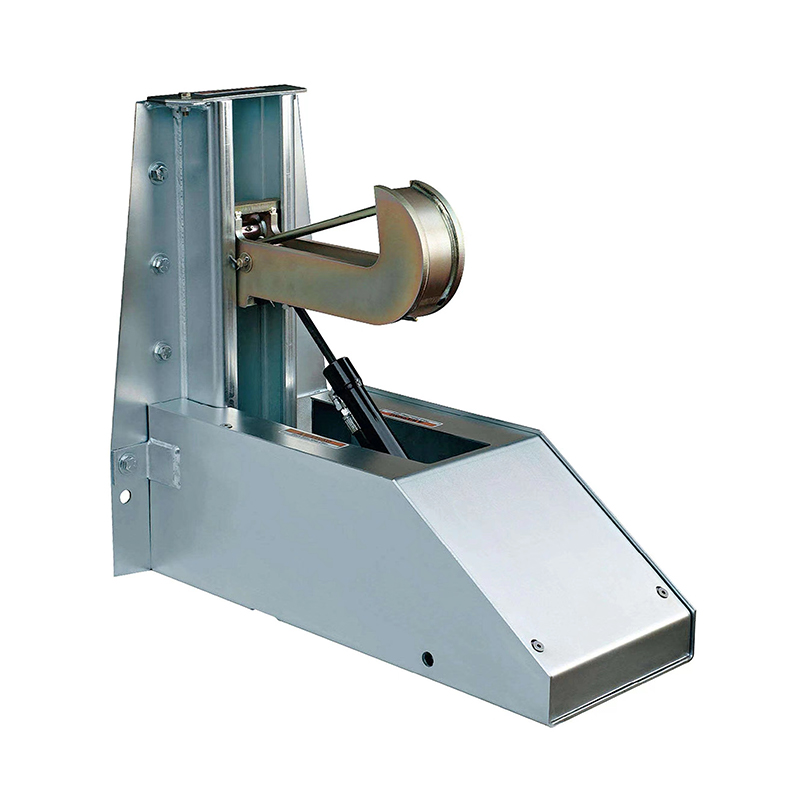

Dock Levelers, simply put, are mechanical devices installed at the interface between a loading dock and the bed of a truck or trailer. Their primary function is to bridge the gap between the dock and the varying heights of incoming and outgoing vehicles, creating a stable and level platform for loading and unloading activities. This eliminates the need for manual lifting or specialized equipment, significantly reducing the risk of accidents and enhancing productivity.

How Do They Work?

Dock Levelers operate using a variety of mechanisms, but the very common involve hydraulics or pneumatics. When a truck pulls up to the dock, the operator activates the leveler, which then extends or raises to meet the truck bed. This creates a seamless, level transition that allows forklifts, pallet jacks, or other material handling equipment to move freely between the dock and truck. Once loading or unloading is complete, the leveler is retracted or lowered back into its resting position.

Why Are Dock Levelers Important?

Dock Levelers are crucial for maintaining efficiency and safety in logistics operations. Without them, loading and unloading would be slower, more labor-intensive, and potentially hazardous. By providing a stable platform, Dock Levelers enable:

l Faster Turnaround Times: By eliminating the need for manual lifting or specialized equipment, Dock Levelers speed up the loading and unloading process, reducing truck wait times and improving overall supply chain efficiency.

l Improved Safety: A stable and level transition point minimizes the risk of accidents involving slips, trips, or falls, protecting both personnel and equipment.

l Reduced Labor Costs: Automated Dock Levelers reduce the reliance on manual labor, lowering the cost of operations and potentially eliminating the need for additional personnel.

l Increased Capacity: Dock Levelers can accommodate a wide range of truck and trailer heights, enabling warehouses to handle a more diverse range of vehicles and shipments.

Conclusion

Dock Levelers are an essential component of modern logistics and supply chain management. Their ability to bridge the gap between loading docks and trucks, combined with their contributions to safety, efficiency, and cost savings, makes them an invaluable asset for any organization involved in the movement of goods. As the demand for faster and more efficient supply chains continues to grow, the importance of Dock Levelers in maintaining the smooth flow of commerce becomes increasingly apparent.

English

English Español

Español Tiếng Việt

Tiếng Việt