Reinforced Structural Design and Load DistributionEOM Industrial Dock Levelers are engineered with...

In the fast-paced world of logistics and warehousing, Dock Levelers play a crucial role in ensuring smooth and efficient loading and unloading operations. They bridge the gap between the loading dock and the delivery vehicle, allowing forklifts and other material handling equipment to move seamlessly from one to the other. Choosing the right dock leveler is essential for safety, minimizing downtime, and enhancing overall operational efficiency. Here's a comprehensive guide on how to choose a suitable dock leveler for your facility.

Assess Your Needs and Requirements

The step in selecting a dock leveler is to thoroughly assess your facility's needs and requirements. Consider the following factors:

l Frequency of Use: How often will the dock leveler be in use? High-traffic docks require more durable and heavy-duty equipment.

l Capacity Requirements: Determine the weight your dock leveler needs to support, including the weight of the forklift and its load.

l Vehicle Variations: Will you be handling a variety of truck sizes and types? A versatile dock leveler can accommodate different heights and widths.

l Space Constraints: Measure the available space at your loading dock to ensure the dock leveler fits comfortably without compromising safety.

Understand Dock Leveler Types

There are several types of Dock Levelers, each with its own unique features and applications:

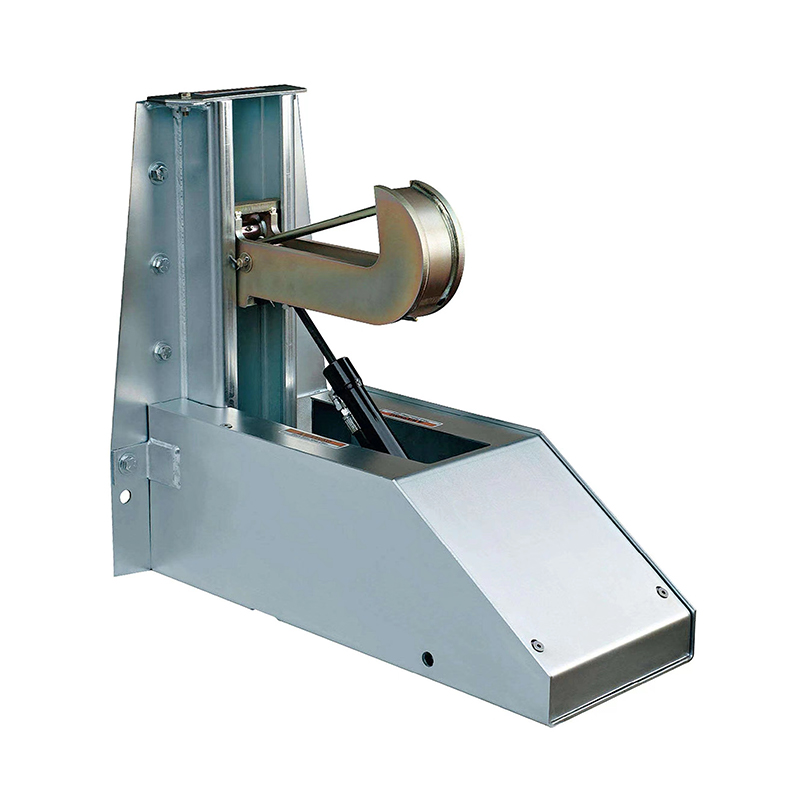

l Hydraulic Dock Levelers: These are the common type, using hydraulic power to raise and lower the platform. They are suitable for heavy-duty applications and can be customized to fit various heights.

l Mechanical Dock Levelers: Operated manually or with a spring-assisted mechanism, they are more affordable but may not be suitable for high-frequency or heavy-duty use.

l Air-Powered Dock Levelers: Ideal for cold storage environments where hydraulic fluid can freeze, they use compressed air to power the lifting mechanism.

l Vertical Storing Dock Levelers (VSDLs): Perfect for space-constrained facilities, they retract vertically into a pit, minimizing their footprint.

Evaluate Safety Features

Safety should always be a top priority when selecting a dock leveler. Look for features such as:

l Lip Extensions and Hold-Down Devices: Ensure the lip securely locks onto the truck bed to prevent accidents.

l Emergency Stop Buttons: Placed strategically for quick access in case of an emergency.

l Warning Lights and Alarms: Indicate when the dock leveler is in motion, alerting personnel to stay clear.

l Non-Slip Surfaces: On the platform and lip to prevent slips and falls.

Consider Maintenance and Durability

Long-term costs associated with maintenance and repairs should also be factored in. Consider:

l Ease of Maintenance: Look for models with accessible components for routine checks and repairs.

l Warranty Coverage: Check the manufacturer's warranty policy and its reputation for customer support.

l Durability: Choose materials and construction that can withstand the rigors of daily use and the elements.

Compare Costs and Suppliers

Finally, compare the costs of different Dock Levelers from reputable suppliers. Don't solely base your decision on the initial purchase price; consider the total cost of ownership, including installation, maintenance, and potential downtime due to malfunctions.

Conclusion

Choosing a suitable dock leveler is a critical decision that can significantly impact the efficiency, safety, and profitability of your logistics operations. By assessing your needs, understanding the various types of Dock Levelers, evaluating safety features, considering maintenance and durability, and comparing costs, you can make an informed decision that meets your facility's unique requirements. Remember, investing in high-quality Dock Levelers can pay dividends in the long run by reducing downtime, improving safety, and enhancing productivity.

English

English Español

Español Tiếng Việt

Tiếng Việt